PRODUCTION COMPANIES

Workforce management system for production

INCREASE PRODUCTIVITY AND CONTROL OF PRODUCTION

Time Harmony is a work management system for production that measures activities, optimizes processes, and facilitates team management.

MANAGING A PRODUCTION TEAM

TIME AND TASK CONTROL

Benefits of measuring efficiency and activities in production with Time Harmony

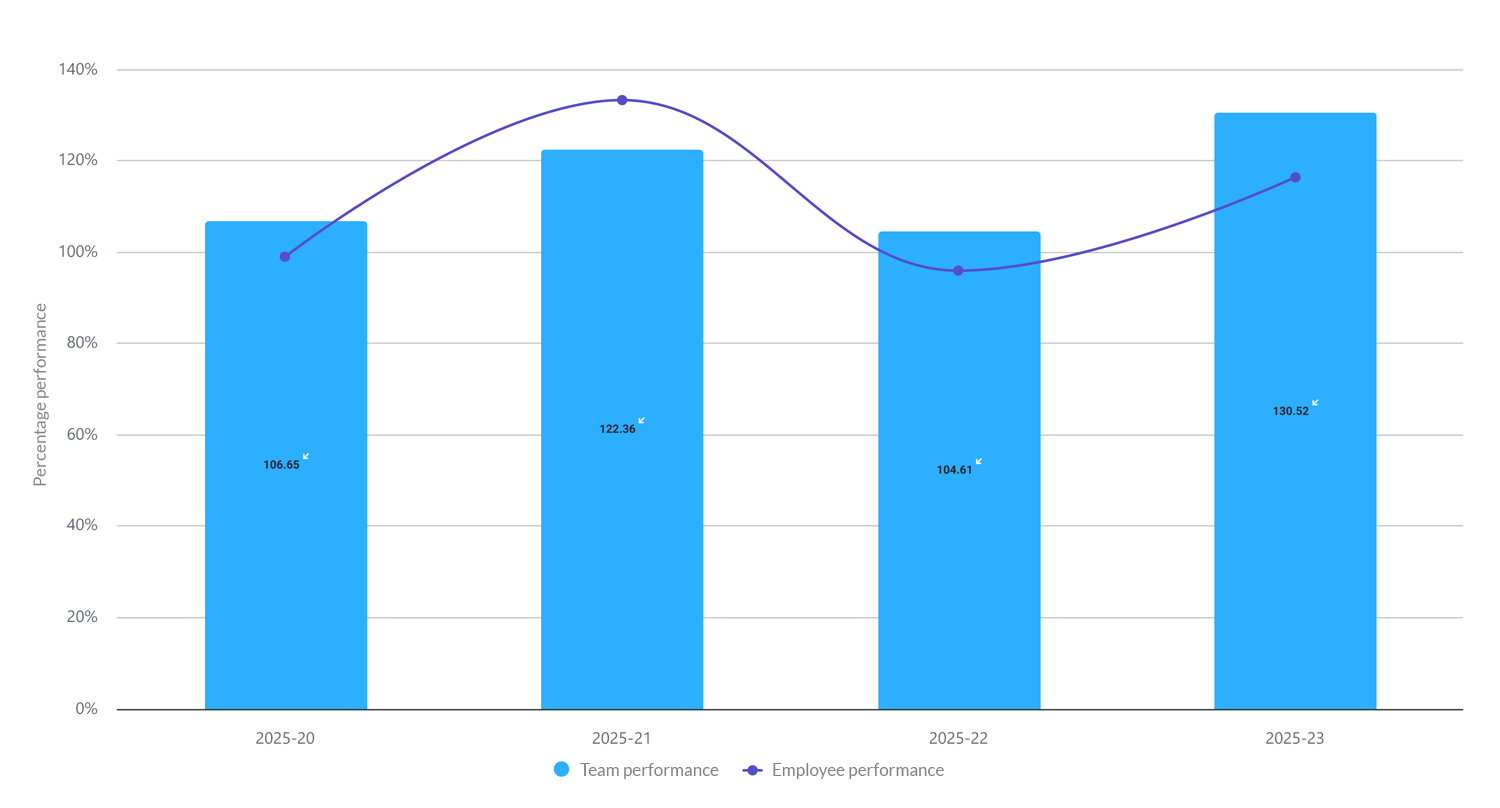

Increase in work efficiency

Identify bottlenecks and time-consuming activities. Implement changes based on facts, not guesswork.

Precise data for billing and bonuses

Measure the individual contribution of the employee to the process and link it to the motivation system.

Process optimization

See which production steps are the least efficient and take improvement actions.

Reduce operating costs

By analyzing working times and processes, you will reduce the waste of time, resources and energy.

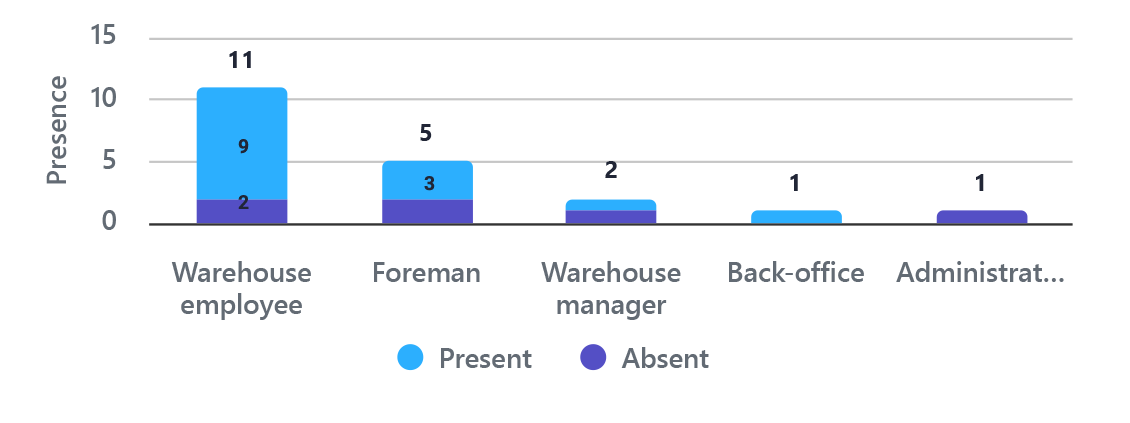

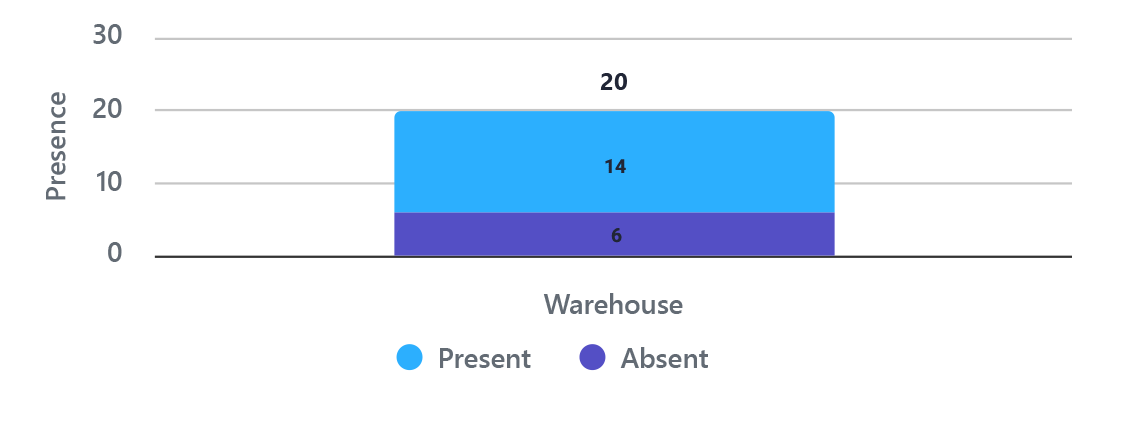

Efficient staffing planning

Based on the performance data, plan staffing, verify the load, and make the necessary adjustments.

Compliance with the Labour Code

The system complies with the regulations on work monitoring – it meets the information obligation and protects employee data.

PROCESS AND TEAM OPTIMIZATION

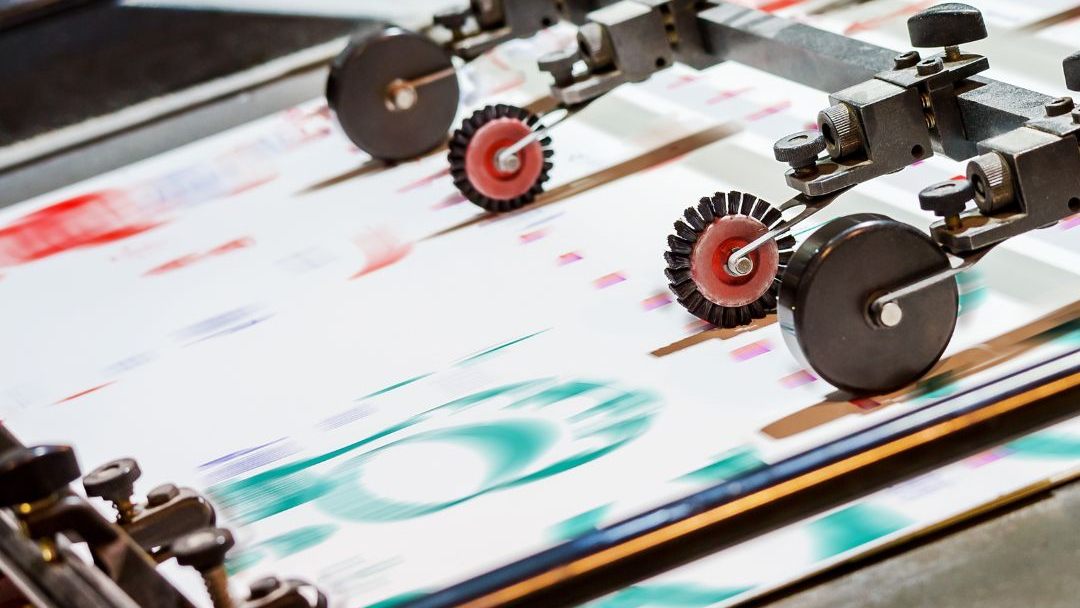

Time Harmony - a system for managing work and time in a production company

The time and attendance (T&A) system in Time Harmony is just the beginning. Our solution also enables comprehensive measurement of the actual time of work at the workstation, measurement of efficiency and the duration of processes and completed orders. This gives you a complete, reliable picture of the performance of your entire production facility.

CONTINUOUS IMPROVEMENT STARTS WITH MEASUREMENT

Why does measuring production processes matter?

Without accurate data, it's hard to manage performance. With Time Harmony, you know how long each activity takes, how processes are functioning, and where waste occurs.

Full control over your workflow

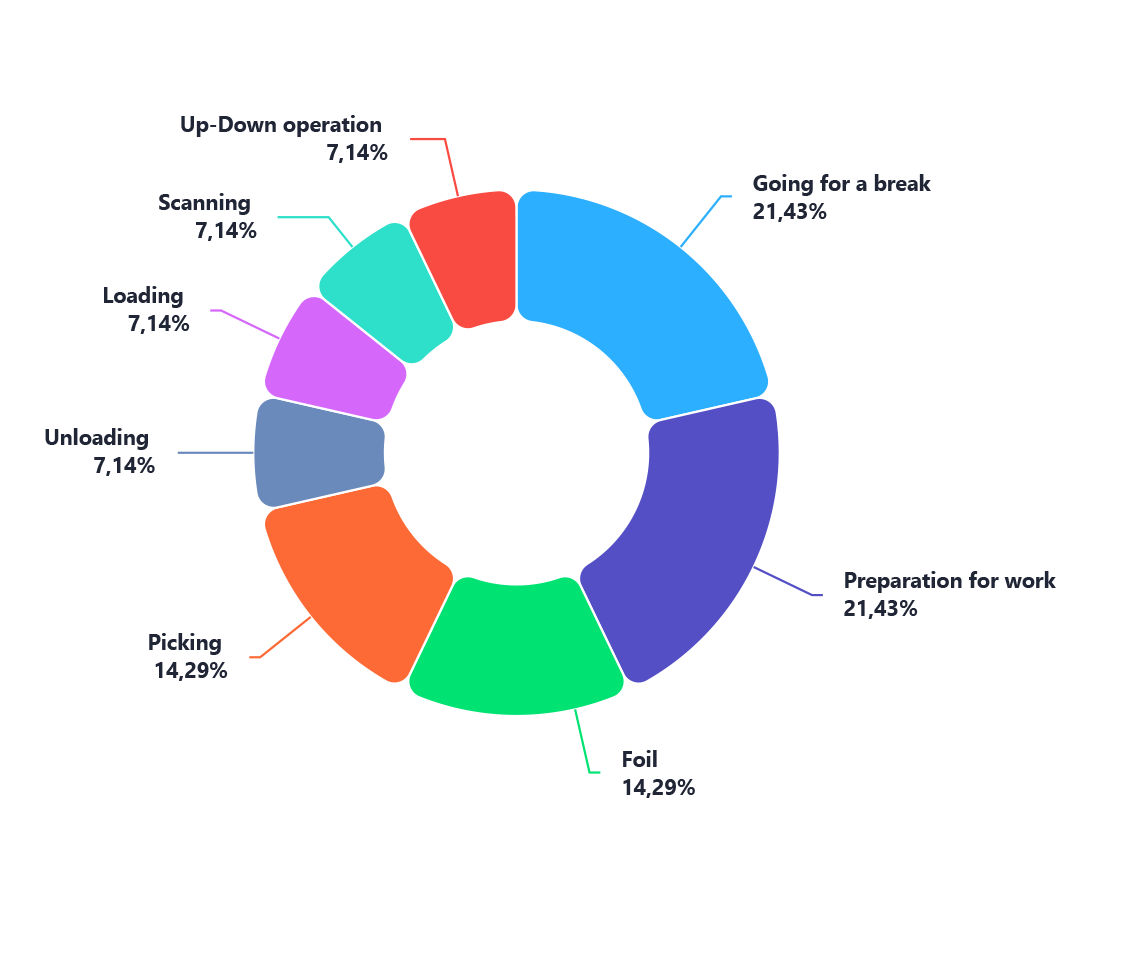

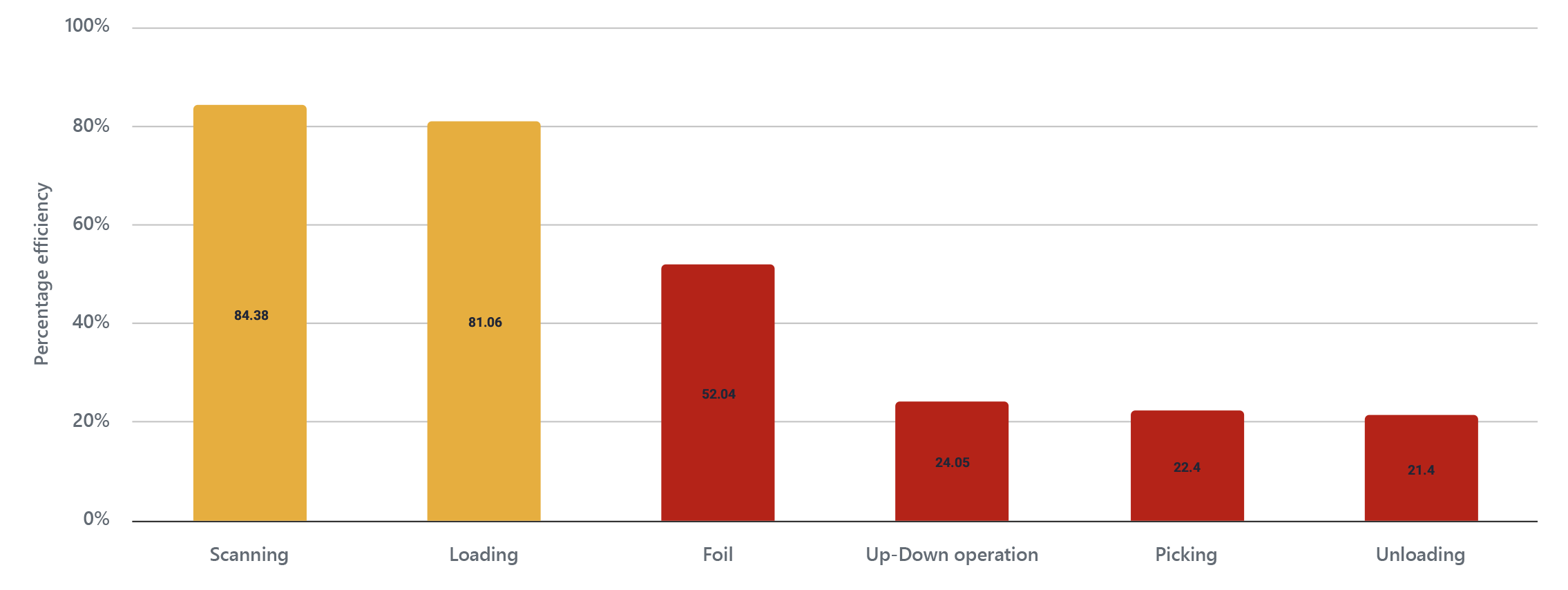

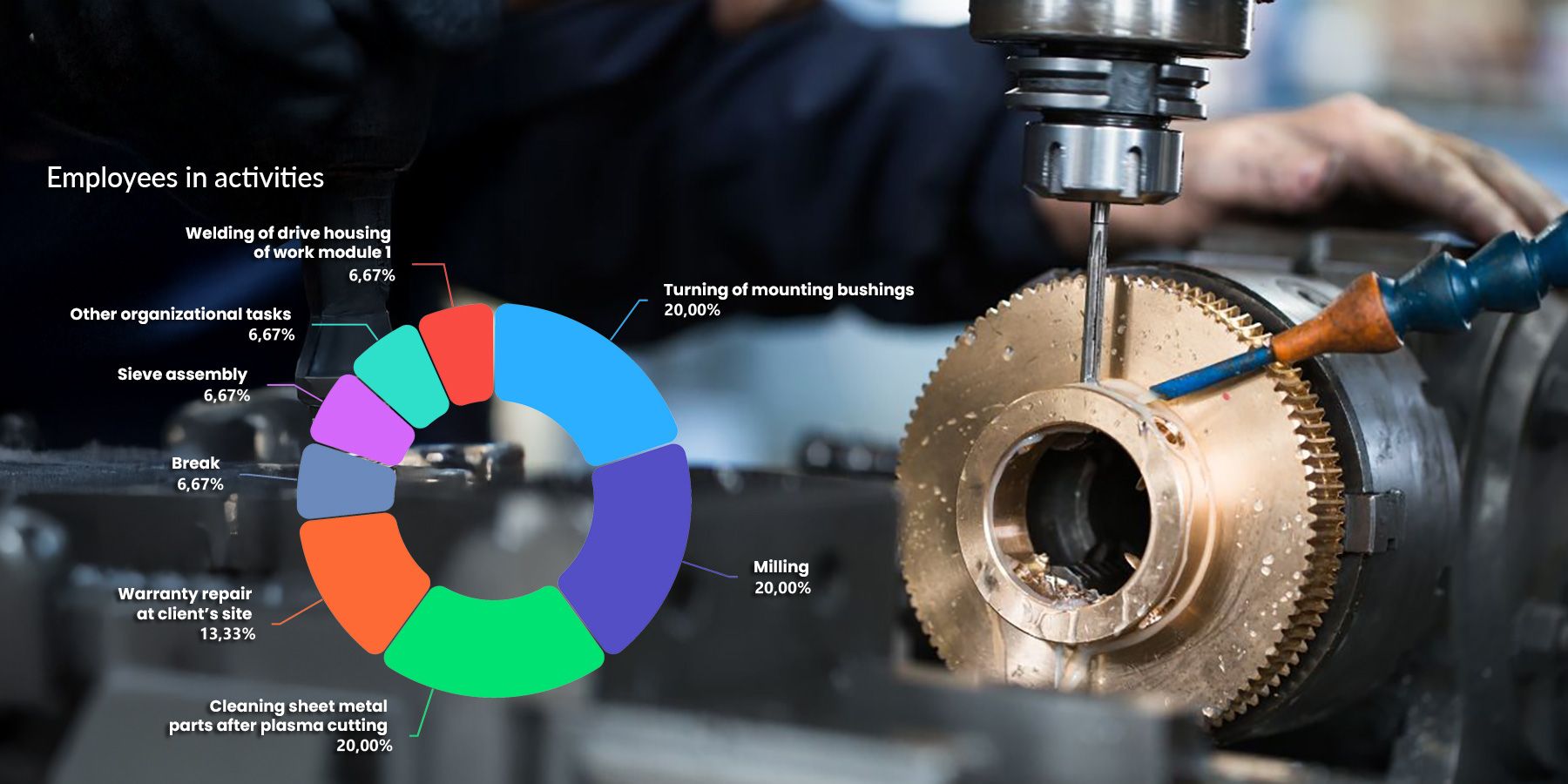

With detailed process measurements, you know what's really happening on the shop floor, which activities are crucial and which are wasteful.

Reliable data for management decisions

Instead of relying on estimates, you get specific efficiency and operational time metrics that support production optimization.

Reduce costs and eliminate downtime

Process monitoring allows you to identify bottlenecks, delays and inefficient activities that translate into real financial losses.

LEAN MANAGEMENT IN A MANUFACTURING COMPANY

Lean is not a theory – it's a data-driven practice

Implementing lean management requires reliable data. Time Harmony is a system that delivers them in real time – from the workstation, the process and the entire production line. As a result, it supports companies in building a culture of continuous improvement and elimination of waste (muda) in accordance with lean principles.

With Time Harmony, you get a tool that allows production teams to operate according to the lean philosophy every day. Measure, analyze, and optimize – no guesswork, no compromise.

CASE STUDY

A system for managing work in production is a real competitive advantage. Learn about proven implementations that show how to effectively manage a team and work on the production floor.

Collection of information on the number of units of an item produced. Identification of defective entities.

Optimization of working time,

elimination of inefficiencies, increased control over production.

Control over the duration of production stages. Better determination of order profitability. Accurate data for project pricing.

Find out how measuring activities and processes in a manufacturing company translates into tangible savings.